Durable & Robust

Reduces Waste, Increases Profitability

Exceptional Output, 50L per min

Product Specification:

Maximum product viscosity: 13,000 Cst.

Maximum product temperature: 100 Celcius.

Ideal for 200L Drums and 1,000L IBC’s.

Decanting Pump Output: 195L @ 1000 cSt per minute.

Includes rinsing kettle with weigh scale option from 500 litres to 1,000 litres.

Levels of precision, repeatability and hygiene that are extremely difficult to match manually.

Time-efficient cleaning: when the lance exits the drum it enters the rinsing kettle, where it cleans itself inside and out, ready for use on another product.

When nearing empty, the drum can be tilted to ensure that maximum product removal is achieved, and the drum is then Dosing Pump rinsed with hot base oil to minimise product waste.

Find out more about the technical features which enable

the Drum Decanting Unit to improve your decanting

speeds here >>>

Please Note: This machine can be made ATEX compliant for flammable products.

Lutz Drum and Container Pumps

Concern for safety and reliability plus responsible response to change have been the underlying factors which have helped us become an internationally successful company. Our faithful adherence to these concerns in fulfilling the needs of our customers has provided and will continue to provide the bedrock for sound innovative ideas. Lutz is the reliable partner in the field of professional liquid handling. As supplier of innovative and high quality pumps and pump systems we support our customers.

You can count on Lutz already for a long time.

Accurate work is very important today in laboratory as well as in production and in the handling of fluids. Flow measurement therefore has to be rational, economical and – above all – practical, in mobile use as well as in stationary operation. The precise detection of the liquid delivery ensures the quality of the work processes and the economical handling of the operating resources.

For thick and thin-bodied media.

Even if it comes „thick and fast“: In any situation at all, the oil-free valve technology of Lutz double diaphragm pumps guarantees unobstructed, infinitely variable operation. These pumps are capable of delivering even critical material to be conveyed in a gentle and safe manner. They are equally well suited for aggressive, abrasive or easily inflammable fluids and for media with a high viscosity.

ATEX Drum Pumps & Motors

FLUX manufactures a range of drum and container pumps for use in ATEX zoned areas (to ATEX Directive 2014/34/EU). These products are notified by the red Ex symbol. Detailed information can be found by clicking the product tabs below.

All FLUX ATEX pumps are constructed from 316 Stainless Steel. Pumps for low viscosity applications include the FP 424, F 430 S and F 425 Series. F 430 S FOOD is also approved for sanitary use (EC 1935/2004 standard) and is particularly well suited to pumping alcohols. ATEX certified drive motors include electric commutator motor F 460, brushless motor FBM 4000 and compressed air motors F 416 and FPM.

The ATEX Directive 2014/34/EU

The ATEX Directive requires equipment intended for use in explosive atmospheres to be designed and manufactured to minimize the occurrence and severity of accidental explosions. It applies to new equipment intended for use in explosive atmospheres such as electrical components and machinery.

An ‘explosive atmosphere’ is a mixture of flammable substances (gases, vapours, mists or dusts) with air, under atmospheric conditions capable of causing a hazardous explosion if ignited. ‘Equipment’ is equipment capable of igniting the explosive atmosphere under normal or fault conditions (in this case the pump and motor, which are placed into the explosive atmosphere).

Standard 2014/34/EU defines technical measures for

assessment and reduction of explosion risks. Articles and other annexes within the Standard define the certification procedures that manufacturers have to apply. Equipment that complies with the ATEX Directive can bear the CE and red Ex markings. Further markings form a code defining the suitability of the equipment for different types of explosive atmospheres.

FLUX ATEX Drum Pumps & Motors for hazardous areas:

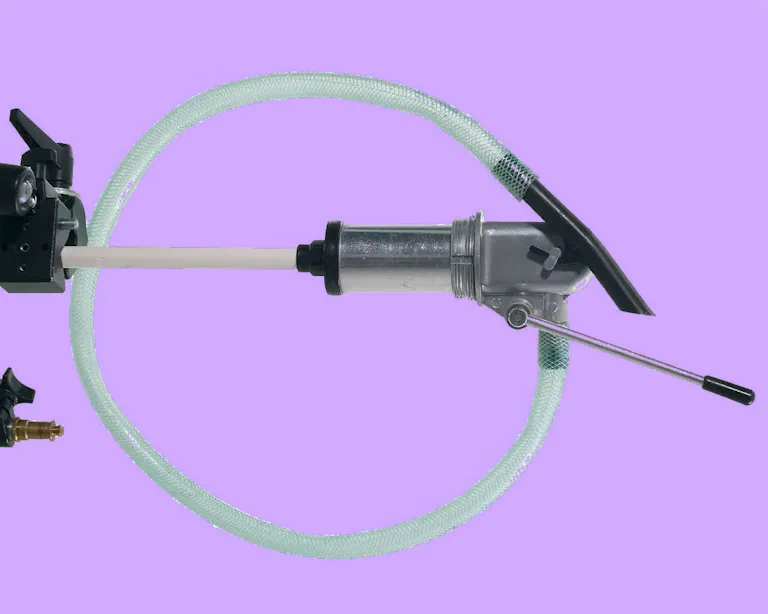

Sealless Drum pump

Drum pump sealless

F 424 / FP 424 for pumping only one medium

Drum pump for 99.98% drum emptying

F 425 / FP 425

Drum pump for mixing and/or pumping

F 426

Drum pump with mechanical seal

F 430 / FP 430 for frequent medium changes

Drum pump for dry installation/horizontal use

F 430 TR

MINIFLUX

For horizontal use at the IBC

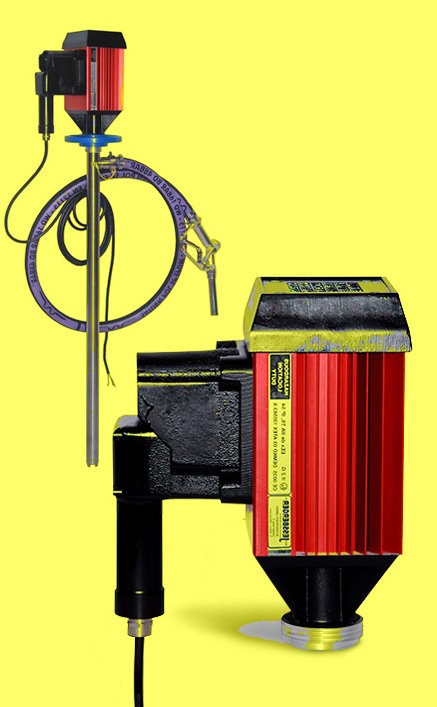

F 460 Ex

The explosion-proof commutator motor

Motor FBM 4000 Ex

The world’s first brushless drum pump motor

Motor F 416 Ex

Compressed-air motor

ATEX Stainless Steel Power Drive Drum Tipper

A large multinational company approached us to design and manufacture a piece of ATEX equipment for their drum handling process.

Experience supplying ATEX equipment

We have many years of experience in supplying industry-leading ATEX drum handling equipment. Our ATEX equipment can be either manual-hydraulic or pneumatic-hydraulic powered. For all bespoke work, we provide 3D CAD approval drawings for your review before manufacture. See the below case study showing a recent piece of equipment we designed and manufactured.

Job particulars atex barrel decanting :

Drums needed to be lifted and tipped into a process vessel that was 3070mm high.

A safe working load (SWL) of 350kg was required based on the heaviest drums being handled.

The unit was to be used in a good manufacturing practice (GMP) area and therefore a stainless steel 304-grade construction was requested.

The area contained flammable/explosive materials and as such the handling equipment needed to be ATEX compliant.

Due to the required speed of planned operations, a power drive system was requested.

Rear controls on the Stainless Steel Telescopic Power Drive Drum Tipper

3500mm of lift height was provided for the tall decanting height.

Telescopic Power Driver Drum Tipper at full height

Constructed from stainless steel with an aqua blasted smooth clean finish.

Pneumatic power drive system

For use in an ATEX environment, we supplied this model with a pneumatic-hydraulic power pack. The hydraulic system powered the drive wheel with controls being mounted in the tiller assembly. Pneumatic drive systems are complex to manufacture but are a more cost-effective solution than an electric system when ATEX is a requirement. In order to power the various functions, an airline connection is required.

The tiller controls featured two levers for forwards and reverse; the unit also had a horn to warn personnel in the vicinity.

Stainless Steel power drive tiller on drum tipper

Pneumatic-hydraulic tiller controlled drive system.

Head rotation controls

For this machine, drums needed to be tipped at height near the opening of a large vessel. By adding head rotation controls operators could tip drums while monitoring the quantity entering the vessel. We can tailor the position of rotational controls on all our drum lift and tip models. The operate button shown in the picture was added as a safety feature, this ensured that the rotation function was not operated by mistake at any time.

Stainless Steel Power Drive Drum Tipper with twin controls on drum tipper head

This model included head-mounted tip and return controls.

Training video

A full operation and training video was supplied with the equipment to show the correct usage. A video is also a great way to refresh operators with how best to use the equipment in the future.

Stainless Steel INOX (GMP), Powered Pneumatic Hydraulic Drum Tipper, ATEX Compliant

PLAY VIDEO

Get in touch

If your company requires a piece of bespoke ATEX equipment please get in touch with our team. We will happily discuss your requirements and advise on the most suitable piece of equipment for your application. Alternatively, take a look at our standard range of ATEX handling equipment and let us know what interests you.