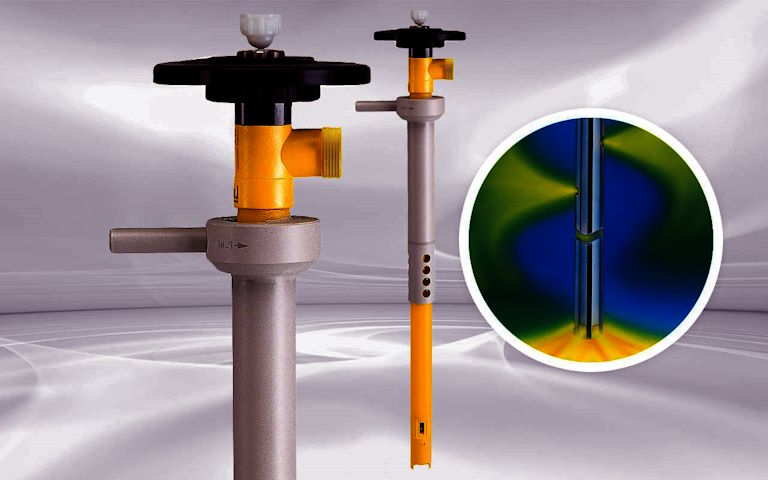

Barrel pumps are a vital tool in various industries that are used to transfer and handle liquid materials from barrels and tanks. Polypropylene (PP) material is one of the main choices for making these pumps due to its unique properties. In this article, we have examined the features, applications and importance of barrel pumps with polypropylene material.

Properties of Polypropylene (PP)

Definition of polypropylene

Polypropylene is a thermoplastic polymer that is used in many industrial applications due to its unique properties. Polypropylene is known as a plastic material with high resistance to chemicals, heat, and impact.

Polypropylene properties

- High chemical resistance : Polypropylene has high resistance to many chemicals and solvents, which helps improve the useful life of pumps.

- Heat resistance : Polypropylene has high heat resistance and the ability to function at various temperatures.

- Lightweight : Due to its lightweight, polypropylene helps reduce the overall weight of pumps, making them easier to transport and install.

- Mechanical strength : Polypropylene has high mechanical strength and impact resistance, which helps increase the durability and efficiency of pumps.

- Non-absorbent : Polypropylene has waterproof properties and does not absorb moisture, which helps improve the performance and service life of pumps.

Features of barrel pump with polypropylene material

1. Corrosion resistance

One of the outstanding features of polypropylene barrel pumps is their high resistance to corrosion. These pumps can withstand the chemical effects of various materials and prevent damage and deterioration caused by corrosion.

2. Lightweight and portable

Polypropylene helps reduce the overall weight of barrel pumps due to its light weight. This feature makes the pumps easy to transport and install.

3. Compatibility with various chemicals

Polypropylene has high compatibility with various chemicals. This property allows the drum pump to perform well in mixing and transferring a variety of chemicals.

4. Economical and cost-effective

Barrel pumps made of polypropylene have lower production costs than other materials. This feature helps reduce overall costs and increase economic efficiency.

5. Heat resistant

Polypropylene has high heat resistance, which allows the barrel pump to function well at different temperatures and not be affected by heat.

Applications of barrel pump with polypropylene material

1. Chemical industry

In the chemical industry, barrel pumps made of polypropylene are used to handle and transfer various chemicals such as acids, bases and solvents. The high chemical resistance and handling accuracy of these pumps help improve the efficiency and safety of chemical processes.

2. Food and beverage industry

In the food and beverage industry, polypropylene barrel pumps are used to move food and beverages. These pumps help improve product quality and increase productivity due to their waterproof and chemical-resistant properties.

3. Pharmaceutical industries

In the pharmaceutical industry, polypropylene barrel pumps are used to handle pharmaceuticals and sensitive solutions. The chemical and thermal resistance of these pumps helps improve the quality and safety of pharmaceutical products.

4. Oil and gas industries

In the oil and gas industry, polypropylene barrel pumps are used to move oil, gas, and various chemicals. These pumps help improve the efficiency and safety of oil and gas processes.

5. Water and wastewater industries

In water and wastewater treatment systems, polypropylene barrel pumps are used to move chemicals used in water and wastewater treatment. These pumps help improve water quality and reduce environmental pollution.

Advantages of using a barrel pump with polypropylene material

1. Improve efficiency and accuracy

Using a barrel pump with polypropylene material helps improve the efficiency and accuracy of material handling. These pumps can move materials homogeneously and uniformly, which leads to improved performance and reduced material waste.

2. Reduce maintenance costs

Due to the high resistance and long life of the barrel pump with polypropylene material, the need for repairs and replacement of pumps is reduced. This feature helps reduce maintenance and repair costs and increases economic efficiency.

3. Increased safety and reliability

The polypropylene barrel pump is safe and reliable due to its high resistance to corrosion and chemicals. This feature helps reduce the risks of chemical leakage and pump failure, and provides stable and reliable performance.

4. Environmental compatibility

Polypropylene, as a durable and resistant plastic material, has a high level of environmental compatibility. Using a barrel pump made of polypropylene material helps reduce the use of harmful chemicals and reduce environmental pollution.

Conclusion

Barrel pump made of polypropylene material is one of the vital tools in various industries that helps in the movement and transfer of liquid materials. The unique properties of polypropylene, including high chemical and thermal resistance, light weight, mechanical strength and waterproofing, help improve the performance and efficiency of these pumps. Using barrel pump made of polypropylene material helps in improving efficiency, reducing maintenance costs, increasing safety and environmental compatibility. By selecting and using these pumps correctly, it is possible to improve the quality of processes and increase productivity in various industries.